Shipyard and port

Industry Chain

Preparatory stage of shipbuilding

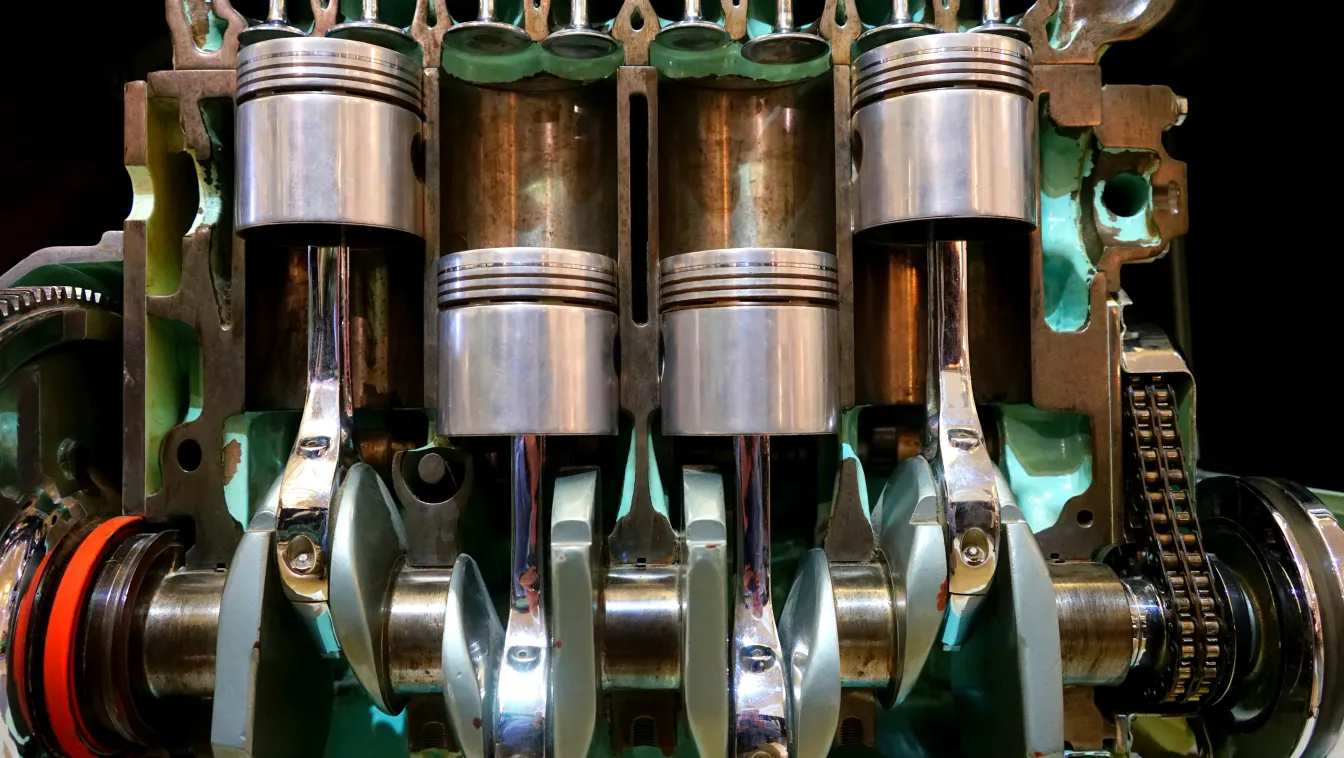

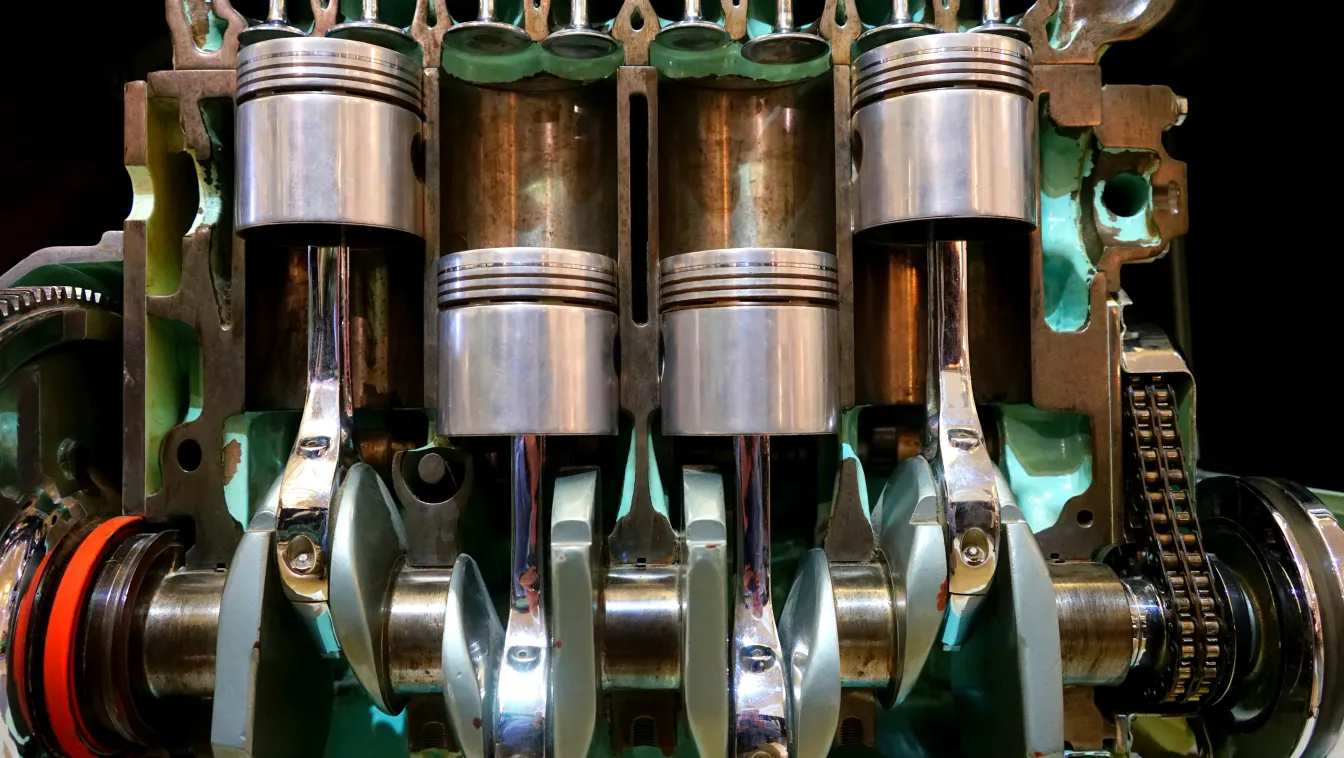

Steel industry raw material supply

Metal mineral mining, iron smelting, steelmaking, steel processing, ferroalloy smelting, steel wire and its products industry, etc.

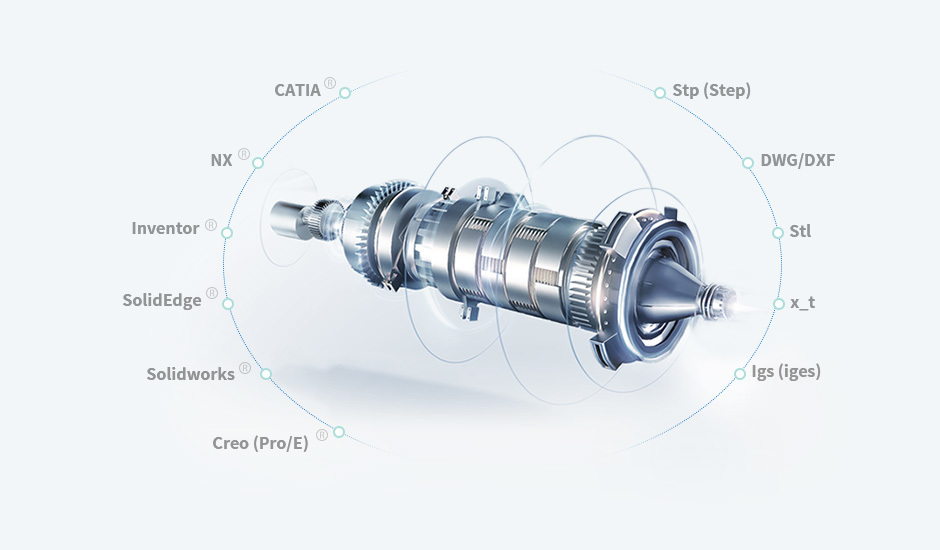

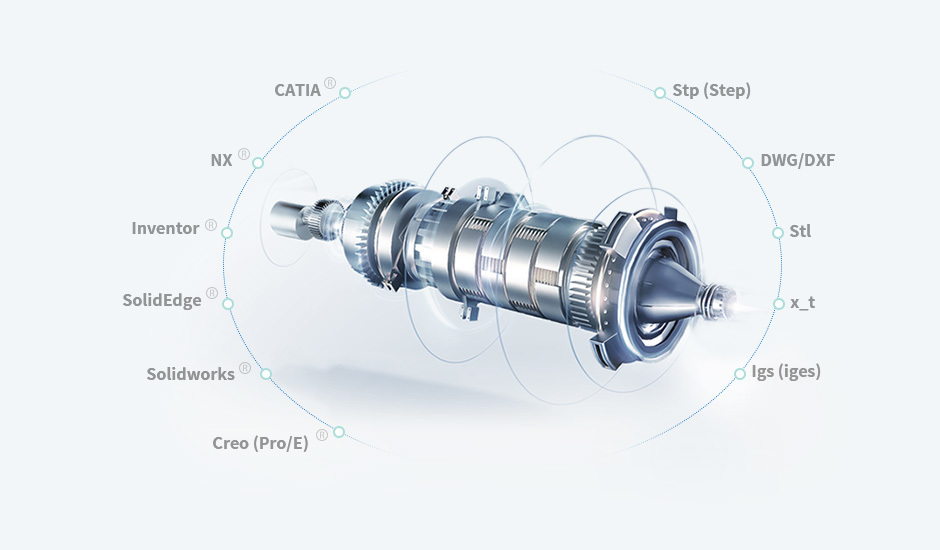

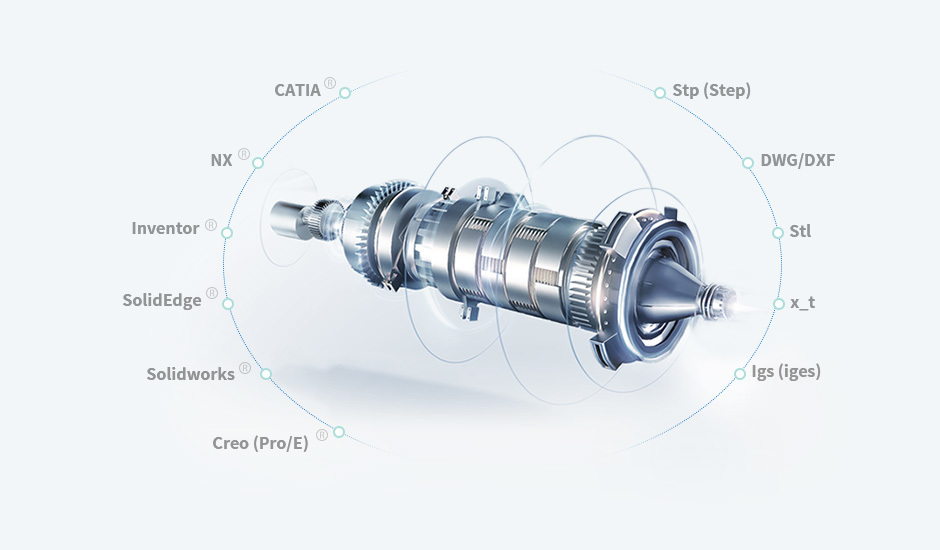

Software manufacturing industry

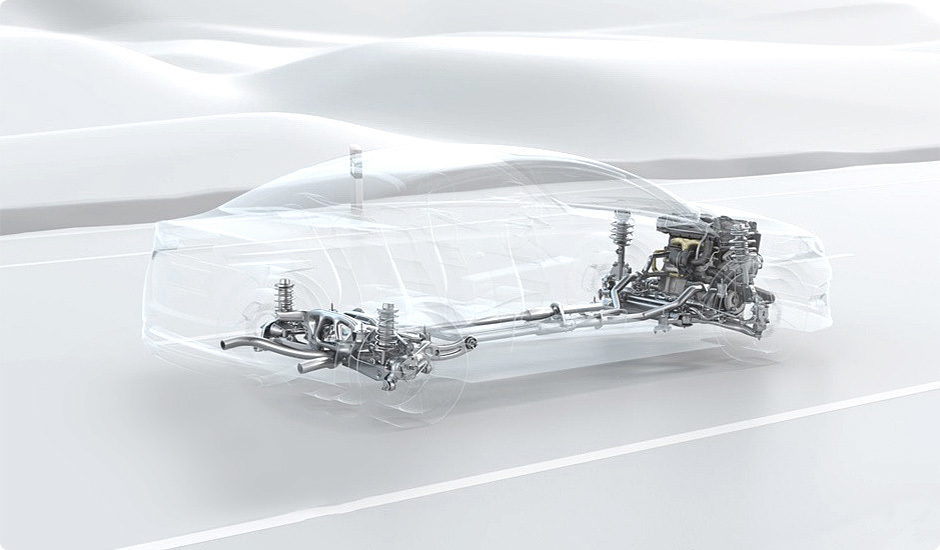

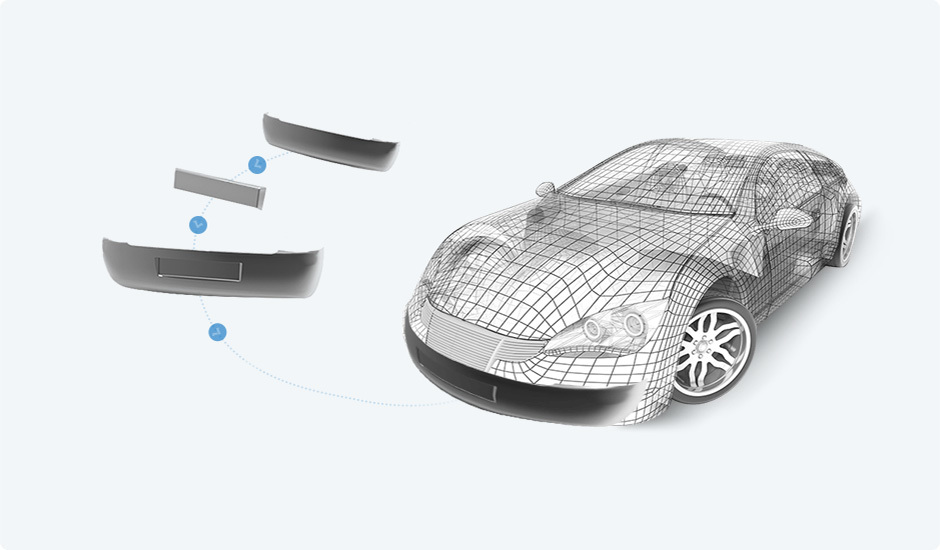

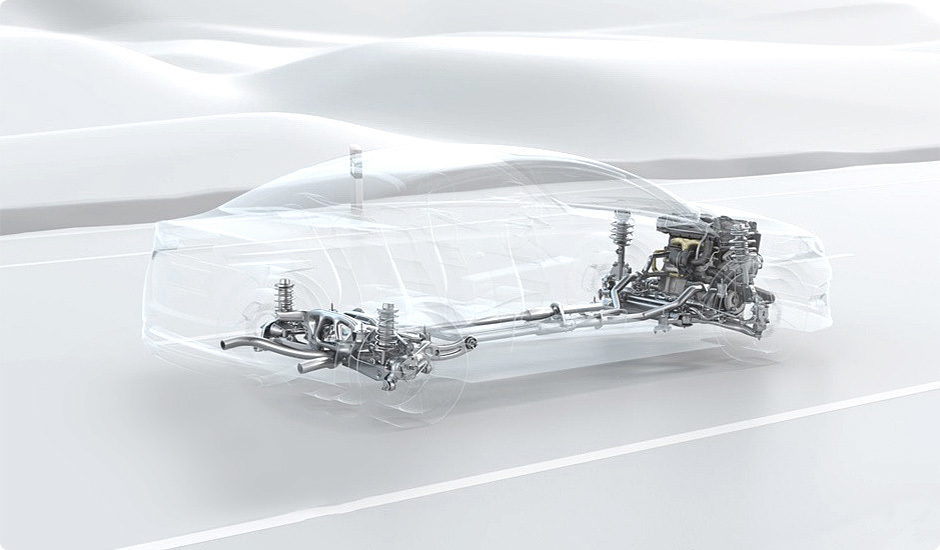

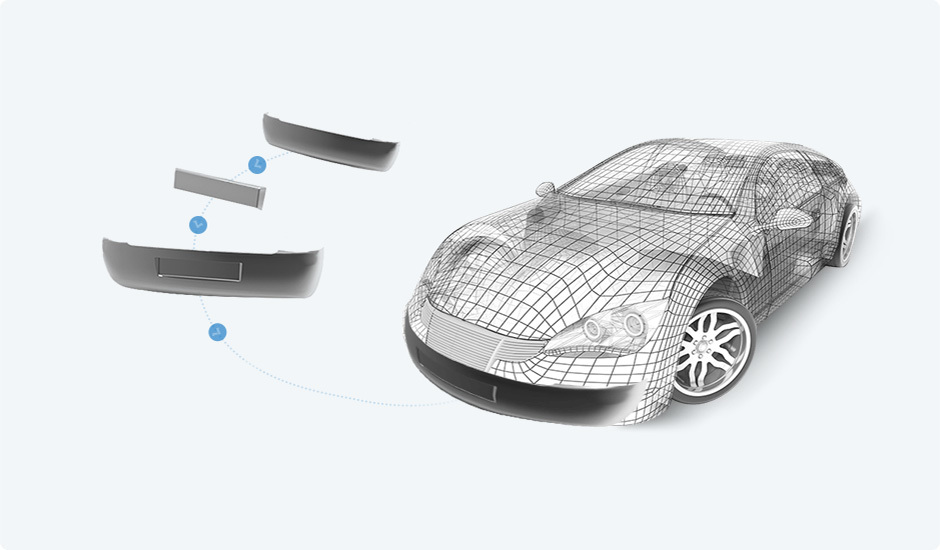

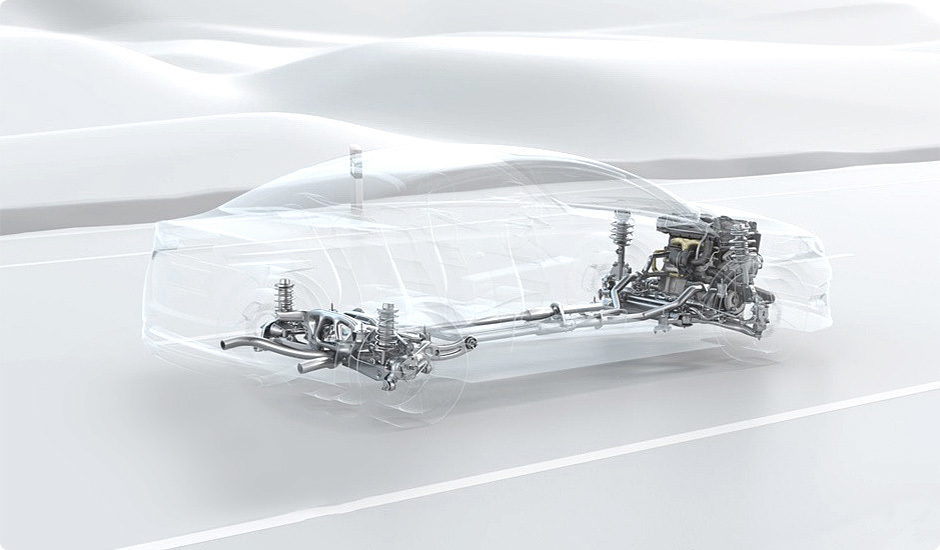

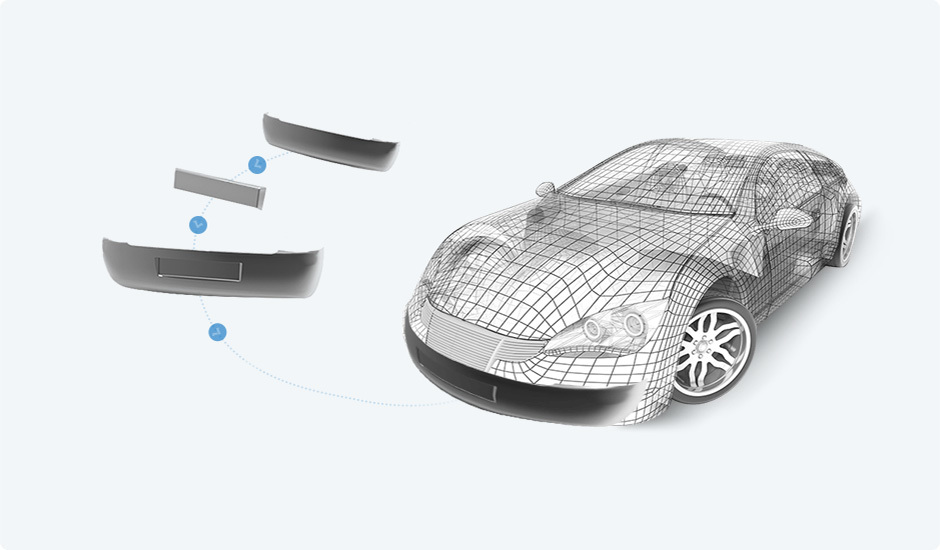

Through digital shipbuilding software, shipbuilders can simulate the entire shipbuilding process in an integrated virtual shipyard before cutting the first plate.

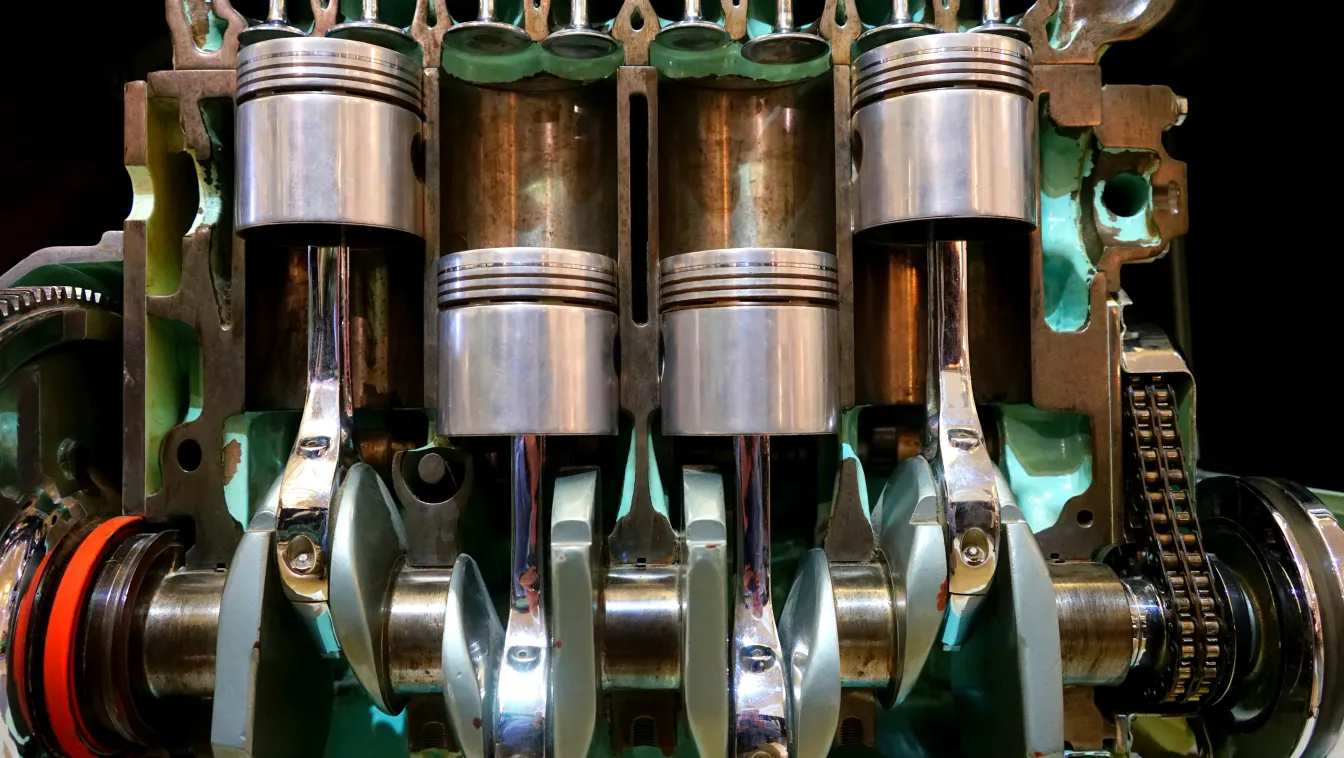

Machinery and electronic component processing and manufacturing industry

Power machinery, lifting and transportation machinery, agricultural machinery, metallurgical mining machinery, chemical machinery, textile machinery, instruments and meters, electronic components, etc.

Ship assembly manufacturing

Transport ships

Ships that carry passengers and cargo, also known as merchant ships. Compared with other transportation tools, its advantages are large carrying capacity and low operating cost.

Engineering work boats

Ships specifically engaged in a certain type of water or underwater engineering, such as waterway maintenance, port operations, water conservancy construction, offshore construction, rescue and salvage, etc.

Fishing boats

Ships and auxiliary vessels used for fishing and harvesting aquatic plants and animals, such as processing, transportation, aquaculture, investigation and enforcement of fishery administration tasks.

End customers of the shipbuilding industry

Shipping

Passenger shipping, cargo shipping

Ship repair

Through digital shipbuilding software, manufacturers can simulate the entire shipbuilding process in an integrated virtual shipyard before cutting the first plate.

Port terminals

With water and land transportation equipment and conditions, allowing ships to safely enter and leave and berth, it is a place for ships to berth, load and unload cargo, get on and off passengers, and replenish supplies.

Industry pain points

Low efficiency of manual hoisting

Unable to ensure personal safety

High labor cost input and low efficiency

Traditional hoisting equipment is backward

Vacuum suction cups have poor adaptability

Grippers and clamps easily damage workpieces

High energy consumption

Electro-permanent magnets are 95% more energy-efficient than electromagnets

Taking a steel plant as an example, it can save 200,000 yuan a year (taking Liugang as an example)

Some applications of electro-permanent magnets in the industry

Solution

Loading and unloading on the C40 machine tool

When loading and unloading workpieces on machine tools (for rough machining of rollers), electro-permanent magnets are required to work in conjunction with robotic arms. The roller workpieces vary in size, and their suction surfaces have irregular, striped patterns. The largest workpiece weighs up to 5 kg. Based on the comprehensive site conditions provided by the customer, Qianhao has selected the model QEPA-C40 as the end-effector gripper for the robotic arm. Its operating voltage is DC 105V, operating current is DC 7A, rated suction force is 20 kg, and its self-weight is 0.7 kg.

Row-arranged Round Billet Electropermanent Lifters

The garden precast has a diameter of 160 mm, lifting 5 pieces at a time—each measuring 9 to 12 meters and weighing 2 tons.

2-ton Full-Coverage Electromagnetic Lifting Device for Steel Plate Loading and Unloading

6m long × 1.5m wide × 5–25mm thickness steel plate for loading and unloading

1.5-ton fully-coverage electro-permanent lifting device for steel plate loading and unloading

6-meter x 1.5-meter x 22mm-thick steel plate for loading and unloading

Customer Cases

Shipyard and port