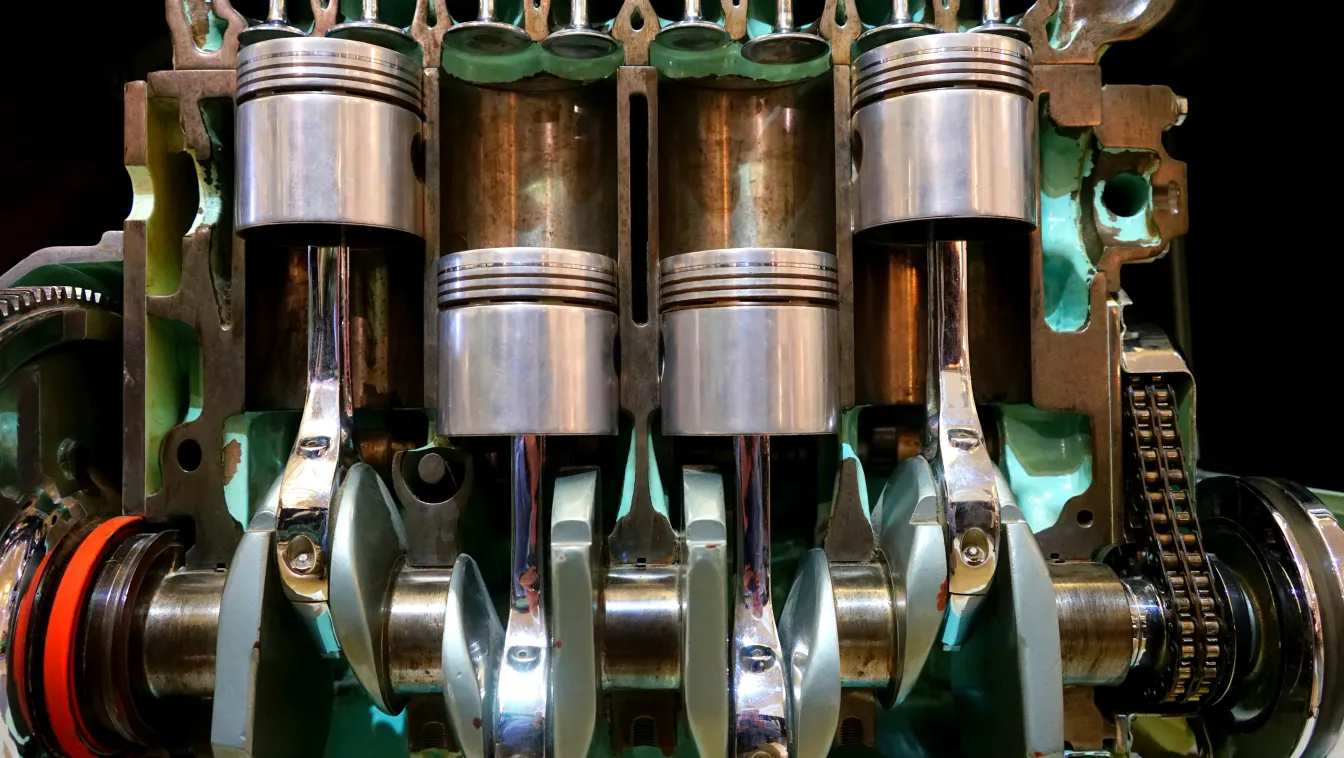

Automotive industry

Industry Chain

Intelligent lifting tools for steel plants

Steel plate lifting

Taking Liugang as an example, Qianhao's electro-permanent magnetic lifter can lift 8 steel plates and accurately place one, requiring only one person to operate the remote control, ensuring personnel safety.

Silicon steel lifting

Taking Wuhan Iron and Steel as an example, facing the uneven surface of vertically placed silicon steel, Qianhao's experiment can lift 20 tons of vertically placed silicon steel with 2mm thick wooden boards.

Lifting

Steel pipe lifting

Taking Tianjin Steel Pipe as an example, in order to solve the high-efficiency requirements of loading, unloading, and stacking, Qianhao magnetic electricity designed an electro-permanent magnetic lifter that can not only lift bundles of steel pipes but also rows of steel pipes.

Production lines of engineering machinery manufacturing enterprises

Manufacturing of various engineering machinery equipment

In the production lines of cranes, road rollers, excavators, bulldozers, etc., from the warehousing and lifting of steel plates to the loading and unloading of laser cutting, to sorting and stacking, and welding, Qianhao magnetic electricity has mature and配套的 electro-permanent magnetic iron equipment to solve them one by one.

Industry application fields

Steel material logistics park

Such as Hunan Yili Logistics, thanks to the precise adsorption and stacking of electro-permanent magnets, the entire logistics park uses electro-permanent magnetic equipment for the handling and sorting of steel materials. Its efficient and precise adsorption capacity reduces manual handling errors, improves logistics efficiency, and enhances personnel safety.

Steel structure processing

In steel structure processing, Qianhao electro-permanent magnets are widely used. In the cutting process, it can quickly fix the steel plate to prevent displacement; during welding, it can accurately position the components to ensure welding accuracy; in the assembly stage, it helps to hoist and connect large steel components, improving processing efficiency and quality.

Industry pain points

Low efficiency of manual hoisting

Unable to ensure personal safety

High labor cost input and low efficiency

Traditional hoisting equipment is backward

Vacuum suction cups have poor adaptability

Grippers and clamps easily damage workpieces

High energy consumption

Electro-permanent magnets are 95% more energy-efficient than electromagnets

Taking a steel plant as an example, it can save 200,000 yuan a year (taking Liugang as an example)

Some applications of electro-permanent magnets in the industry

Solution

Loading and unloading on the C40 machine tool

When loading and unloading workpieces on machine tools (for rough machining of rollers), electro-permanent magnets are required to work in conjunction with robotic arms. The roller workpieces vary in size, and their suction surfaces have irregular, striped patterns. The largest workpiece weighs up to 5 kg. Based on the comprehensive site conditions provided by the customer, Qianhao has selected the model QEPA-C40 as the end-effector gripper for the robotic arm. Its operating voltage is DC 105V, operating current is DC 7A, rated suction force is 20 kg, and its self-weight is 0.7 kg.

Row-arranged Round Billet Electropermanent Lifters

The garden precast has a diameter of 160 mm, lifting 5 pieces at a time—each measuring 9 to 12 meters and weighing 2 tons.

2-ton Full-Coverage Electromagnetic Lifting Device for Steel Plate Loading and Unloading

6m long × 1.5m wide × 5–25mm thickness steel plate for loading and unloading

1.5-ton fully-coverage electro-permanent lifting device for steel plate loading and unloading

6-meter x 1.5-meter x 22mm-thick steel plate for loading and unloading

Customer Cases

Automotive industry