Automated production

Industry Chain

Unmanned Crane Intelligent Lifting

Unmanned Crane Intelligent Lifting

The unmanned crane electro-permanent magnetic lifting device is specially designed for automated handling. It uses electro-permanent magnetic technology to generate strong magnetic force in an instant when energized, adsorbing steel and other metal materials. After power failure, the magnetic force still exists to ensure safe and stable handling. With the cooperation of unmanned cranes, it can achieve precise positioning and fast lifting, improve logistics efficiency, reduce labor costs and safety risks, and is suitable for steel mills, warehouses and other scenarios.

Automatic Identification and Sorting System

Automatic Identification and Sorting System

Heavy industry workpieces are characterized by large shape differences and a wide variety of types. To ensure stable grasping of various types of workpieces, this product uses a self-designed dot matrix electro-permanent magnetic end-effector gripper, which has the advantages of simple structure, high universality, single-point control, stable performance, and plug-and-play. It can achieve flexible grasping of massive workpieces. At the same time, intelligent control based on vision can ensure that the end-effector accurately adsorbs irregularly shaped workpieces and avoids adhesion to surrounding waste materials.

Welding clamping

Welding clamping

Automated robotic arm clamping—Electro-permanent magnet welding fixture, is a very suitable adsorption tool in the steel plate welding process; and can fix steel plates of different sizes and shapes, making the welding process safer and safer. Automatic material picking, positioning, and transfer for fully automated production, electro-permanent magnetic grippers can be optionally configured according to the design magnetic force size for automatic flipping and tapping processes, small size, large suction force, fully meet the requirements of multi-directional layout and prevent welding deformation, one clamping can complete multi-faceted processing; the internal coil does not have a heating problem, eliminating maintenance, and running at near-zero cost;

Industry pain points

Low labor efficiency

Unable to ensure personal safety

High labor cost input and low efficiency

Traditional fixtures are backward

Vacuum suction cups have poor adaptability

Grippers and clamps easily damage workpieces

High energy consumption

Electro-permanent magnets are 95% more energy-efficient than electromagnets

Electro-permanent magnets only require 0.1-0.3 seconds of pulsed current

Some applications of electro-permanent magnets in production lines

Solution

Loading and unloading on the C40 machine tool

When loading and unloading workpieces on machine tools (for rough machining of rollers), electro-permanent magnets are required to work in conjunction with robotic arms. The roller workpieces vary in size, and their suction surfaces have irregular, striped patterns. The largest workpiece weighs up to 5 kg. Based on the comprehensive site conditions provided by the customer, Qianhao has selected the model QEPA-C40 as the end-effector gripper for the robotic arm. Its operating voltage is DC 105V, operating current is DC 7A, rated suction force is 20 kg, and its self-weight is 0.7 kg.

Row-arranged Round Billet Electropermanent Lifters

The garden precast has a diameter of 160 mm, lifting 5 pieces at a time—each measuring 9 to 12 meters and weighing 2 tons.

2-ton Full-Coverage Electromagnetic Lifting Device for Steel Plate Loading and Unloading

6m long × 1.5m wide × 5–25mm thickness steel plate for loading and unloading

1.5-ton fully-coverage electro-permanent lifting device for steel plate loading and unloading

6-meter x 1.5-meter x 22mm-thick steel plate for loading and unloading

Customer Cases

Automated production

Automated production

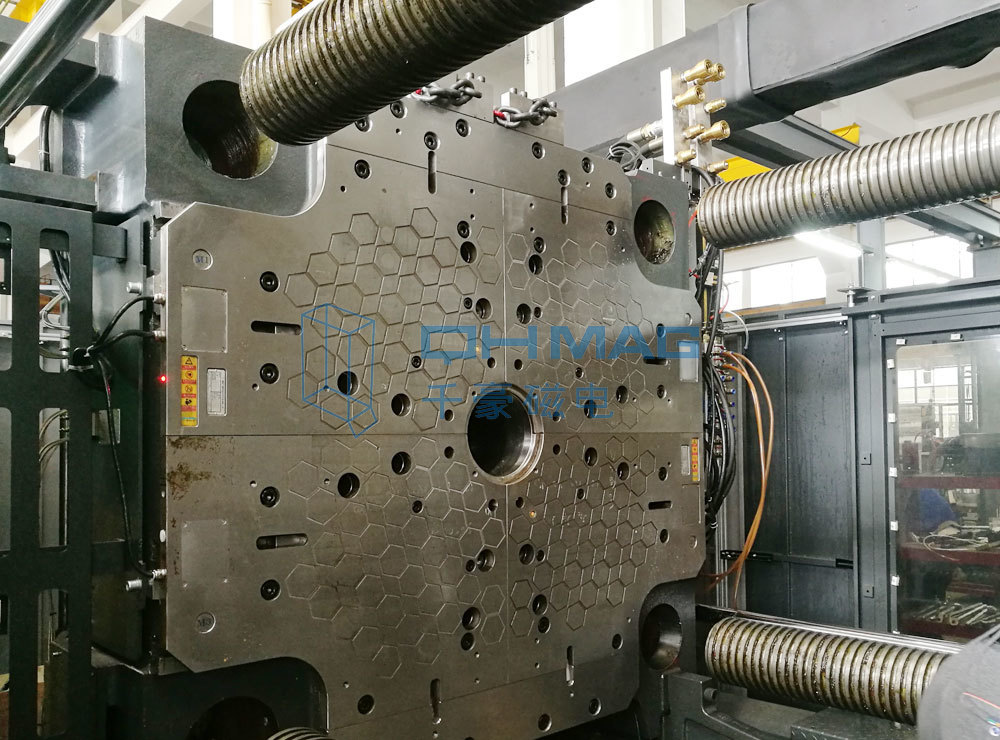

Changsha ShenDa 1400-ton HaiTian two-color machine with quick mold change