Product Features

|

SaferNo magnetic loss after 30 years of power failure |

Ultra Energy SavingMore than 95% energy saving |

Ultra High EfficiencyIncrease efficiency by more than 80% |

Ultra Eco-friendlyClean energy, no pollution |

Ultra IntelligentHigh-sensing technology provides real-time feedback |

More DurablePrevent mold deformation and extend lifespan |

Latest Technology

|

All-steel sealed panel |

Dual magnetic pole technology |

Remote monitoring and real-time feedback |

Human-machine interface visualization |

Patented Product |

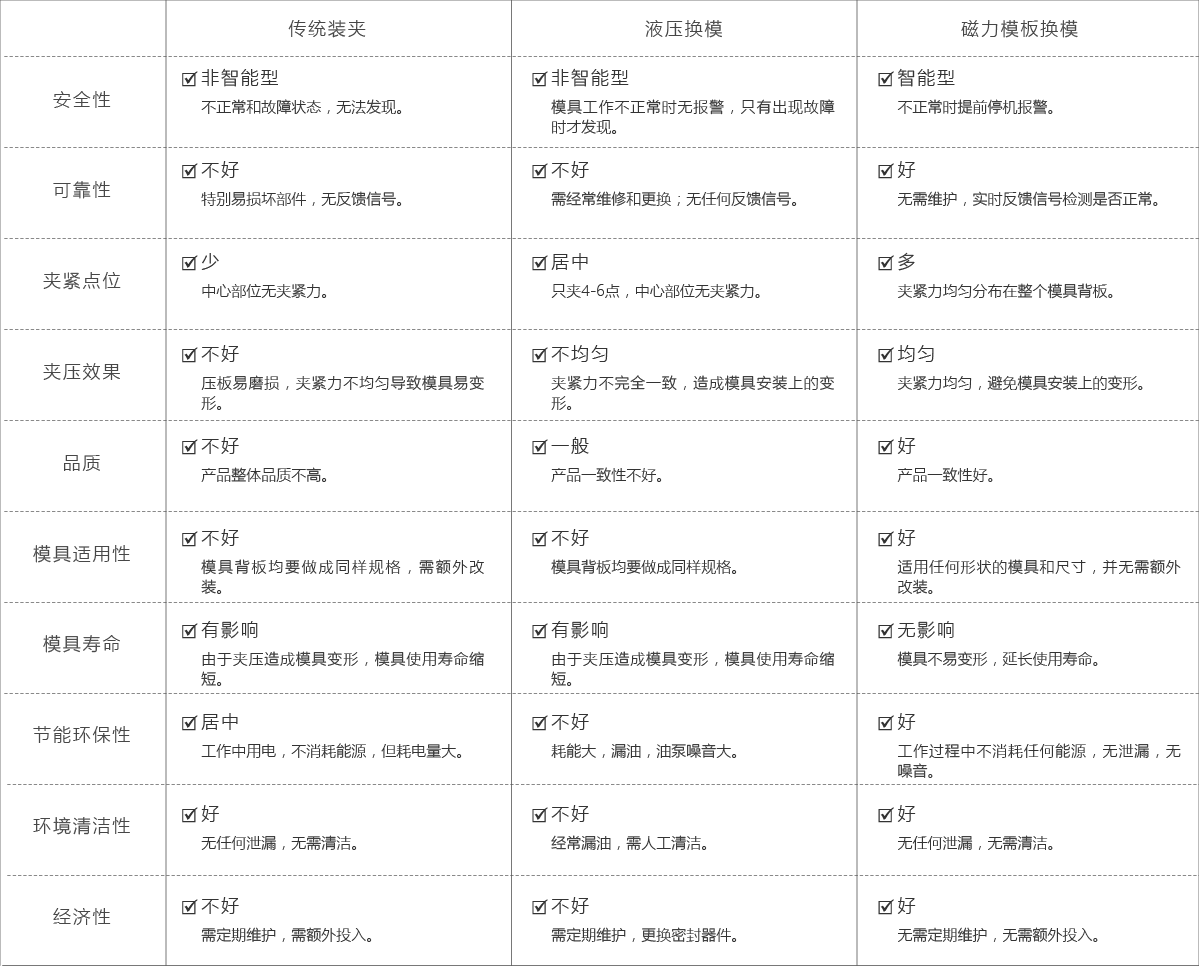

Clamping Method Comparison

Application Range

|

Home appliance manufacturing |

Plastic product processing |

Automotive manufacturing |

Mold manufacturing |

Bearing manufacturing |

Engineering machinery manufacturing |

Shipbuilding |

Smart terminal processing |

Experimental Cases

Take a 3300-ton injection molding machine producing car bumpers as an example:

Traditional mold changing methods typically require 5 people for 4.0 hours to complete;

Using customized quick-change magnetic mold templates only requires 1 person, 20 minutes to complete mold changes.

Product Specifications

| Item |

Square magnetic pole |

Circular magnetic pole |

||||

| Applicable injection molding machine tonnage |

60-280 |

320-900 |

1000-6000 |

60-280 |

320-900 |

1000-6000 |

| Magnetic pole size |

50*50 |

70*70 |

80*80 |

φ74 |

φ74 |

φ74 |

| Magnetic force of a single magnetic pole |

350 |

735 |

980 |

660 |

660 |

660 |

| Magnetic plate thickness |

35-45 |

50 |

52 |

50 |

50 |

50 |

| Maximum operating temperature |

100°C |

100°C |

100°C |

100°C |

100°C |

100°C |

| Magnetic flux depth |

12.5 |

17.5 |

20 |

18 |

18 |

18 |

| Proximity sensor range |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

0.2 |

| Standard voltage |

380V/415V 50HZ/60HZ |

380V/415V 50HZ/60HZ |

380V/415V 50HZ/60HZ |

380V/415V 50HZ/60HZ |

380V/415V 50HZ/60HZ |

380V/415V 50HZ/60HZ |

| Ejection pin (moving mold side) |

Standard |

Standard |

Standard |

Standard |

Standard |

Standard |

| Ejection pin (fixed mold side) |

None |

Provided as needed |

Provided as needed |

None |

Provided as needed |

Provided as needed |

| Control unit |

D4/C8/Display screen |

D4/C8/Display screen |

D4/C8/Display screen |

D4/C8/Display screen |

D4/C8/Display screen |

D4/C8/Display screen |

| Temperature, proximity integrated sensor |

Custom sensor from Italian brand AECO |

|||||

| Magnetic flux sensor |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

| Force measurement |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

| Magnetic pole sealing |

Resin |

Resin |

Resin |

Resin |

Resin |

Resin |

Customer Cases

Metallurgy and Machinery

Cangzhou: Row upon row of round billets being lifted and transported

Metallurgy and Machinery

Learn more about the product