Qianhao Magnetic & VisionBit Intelligent Material Handling and Sorting Line Driven by a Dual-Engine System of "Electropermanent Magnets + Vision" for Upgrading Heavy Industry Manufacturing Intelligence

Data Source:

Author:

Publish Time:

2025.08.14

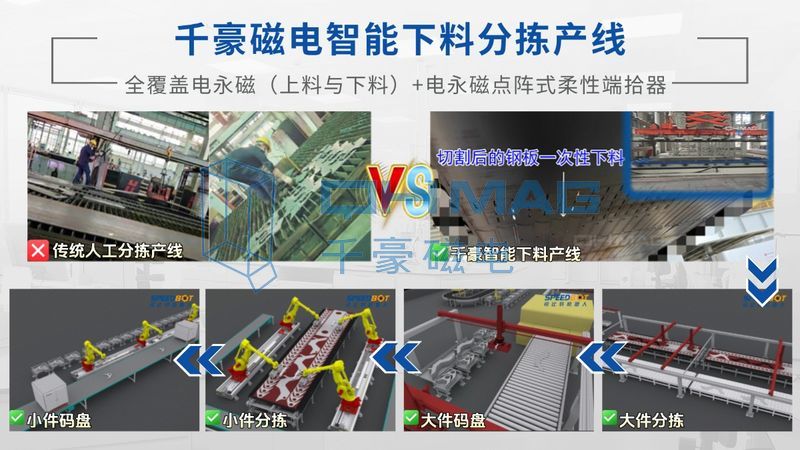

(Yueyang, August 13, 2025) At a critical juncture in the intelligent transformation of the heavy industry manufacturing sector, Hunan Qianhao Magnetic Electric Co., Ltd. (hereinafter referred to as "Qianhao Magnetic Electric") has formed a powerful partnership with VisionBit Robotics. By combining Qianhao Magnetic Electric's decades-long expertise in electro-permanent magnet technology with VisionBit's cutting-edge "AI + 3D Vision" capabilities, the two companies are jointly developing a next-generation smart material handling and sorting production line. This innovative line directly addresses key pain points in the heavy industry—such as low sorting efficiency, high labor costs, and challenges in adapting to diverse environments—by leveraging the deep synergy of "electro-permanent magnet adsorption combined with visual navigation." It enables full-process automation, from workpiece identification and gripping after cutting to palletizing, thereby equipping leading enterprises like Sany Heavy Industry, Zoomlion, and Taiheavy Group with another "smart manufacturing tool" for their advanced, intelligent factories dedicated to heavy machinery production.

I. Directly Tackling Industry Pain Points: "Electropermanent Magnets + Vision" Solve the Sorting Challenge

Traditional heavy industry face-to-face with three core challenges in material handling and sorting: the sheer variety of workpieces—over 10,000 types—with highly complex shapes, making manual identification prone to confusion; the production environment is often filled with oil stains and dust, coupled with unstable lighting conditions, which severely limit the accuracy of conventional vision-based technologies; and the dramatic differences in workpiece sizes—from just a few centimeters to over ten meters—posing significant difficulties for both gripping and palletizing tasks.

Qianhao Magnetic Electric and VisionBit's joint solution delivers a targeted breakthrough: Qianhao Magnetic Electric provides a full range of electro-permanent magnetic gripping equipment, addressing the core challenges of "stable and precise grasping"; while VisionBit offers an AI-powered + 3D vision system, overcoming the technical hurdle of "clear perception and accurate recognition." Together, they create a seamless "perception-decision-execution" loop, enabling robots to perform flexible, human-like operations even in complex environments.

II. Integrated Production Line Core Architecture: Four Key Modules Enable End-to-End Automation

Qianhao Magnetic & Electric—Visbit Intelligent Material Cutting and Sorting Line integrates sanding, inkjet coding, leveling, palletizing, and other comprehensive processes. It consists of four core modules, with each stage leveraging the technological strengths of both partners.

- Small-item sorting module: Leveraging Shibi's multi-arm intelligent collaborative control algorithm and Qianhao's truss-end gripper with electro-permanent magnets, multiple six-axis robots can simultaneously pick up small workpieces. The Qianhao electro-permanent magnet features controllable single-point magnetic force, combined with 3D visual positioning, enabling precise gripping accurate to within 0.5mm—and boosting sorting efficiency by up to 5 times compared to manual handling.

(Figure 1: Qianhao Magneto-Electricity – VisionBit Joint Production Line Small-Item Sorting Module)

- **Small-Part Palletizing Module**: After sanding and inkjet coding, small workpieces are efficiently handled by Qianhao’s electrically permanent magnet dot-array robotic gripper, which leverages its "adaptive suction" feature to flexibly adjust magnetic force distribution according to the workpiece shape. Paired with VisionBit’s dynamic tracking algorithm, this system enables high-speed, synchronized gripping and precise, orderly palletizing. The system also supports real-time monitoring of material bin fill levels, ensuring 100% accuracy in palletizing operations.

(Figure 2: Qianhao Magneto-Electricity – VisionBit Joint Production Line Small-Part Coding Module [Image Watermark: Qianhao Magneto-Electricity])

- Large-Part Sorting Module: For oversized components measuring over ten meters in length, the system employs a fully covering electro-permanent lifting magnet from Qianhao, working in tandem with Visbit’s multi-arm gantry robot. The Qianhao lifting magnet utilizes a clustered magnetic layout to ensure uniform adhesion across the entire plate, preventing any deformation of the workpiece. Meanwhile, Visbit’s multi-source image-matching technology provides coverage of an exceptionally wide 12-meter field of view, precisely guiding the coordinated movement of multiple robotic arms for efficient gripping—reducing the cycle time for single-arm handling to just 6 seconds per pick.

(Figure 3: Qianhao Magneto-Electricity & VisionBit Joint Production Line Large-Item Sorting Module, Image Watermark: Qianhao Magneto-Electricity)

- Large-Part Palletizing Module: After large workpieces are leveled, the Qianhao welding-fixed electro-permanent magnet fixture first calibrates their orientation, followed by path planning for palletizing performed by the VisionBit intelligent scheduling algorithm. With Qianhao’s fixture boasting a rapid 0.3-second charge/discharge magnetic response, combined with sub-millimeter-level positioning accuracy from the vision system, this solution ensures that large workpieces are stacked with an error no greater than 1 mm, while also boosting palletizing space utilization by up to 30%.

(Figure 4: Qianhao Magneto-Optical & VisionBit Joint Production Line Large-Piece Code Disc Module)

III. Technological Synergy Advantages: Bridging the Gap from "Can Do" to "Do Well"

The core competitiveness of the joint production line stems from the technological complementarity between Qianhao Magnetic Electric and VisionBit.

- **Gripping End**: Qianhao Electric Permanent Magnet Equipment delivers the "Three-No Advantages"—no damage (uniform magnetic force prevents workpiece scratches), no energy consumption (power is only used during charging and demagnetizing, achieving 95% energy savings), and no risk (permanent magnetism locks in place even during power outages, preventing drop-offs). Its dot-array end effector features independent single-point control, making it compatible with over 99% of non-standard-shaped workpieces.

(Figure 5: Qianhao Magnetic-Electric Matrix-Type Permanent Magnet End Effector [Image watermark: Qianhao Magnetic-Electric])

- **Visual Side**: The VisionBit 3D vision system achieves 100% recognition accuracy and can detect cracks as narrow as 0.5mm. Combined with an AI-powered incremental learning algorithm, it supports online classification of tens of thousands of workpieces while enhancing resistance to oil stains and dust interference by up to 80%. - **Control System**: The intelligent sorting hub jointly developed by both parties integrates real-time equipment status data from Qianhao with VisionBit’s advanced production scheduling algorithms. This enables multi-robot dynamic obstacle avoidance, smart allocation of material bins, and real-time order scheduling, seamlessly connecting to MES/WMS systems—and boosting overall production line efficiency by 400%.

IV. Real-World Benchmark: Validating Value from Lab to Factory

In the laser cutting workshop of a major engineering machinery giant, the integrated production line has been running smoothly for half a year now. By combining Qianhao's electro-permanent magnetic grippers with VisionBit's advanced vision technology, the system achieves full automation—from loading entire steel plates to sorting cut workpieces afterward. This has reduced manpower by 20 workers per shift, boosted sorting capacity fourfold, and increased raw material utilization from 85% to 95%. "Previously, 10 workers would constantly monitor the cutting machines—but now, just one technician can oversee the entire line," said the company’s production manager. He added that Qianhao’s magnetic equipment effectively solves the longstanding issues of "insecure gripping and easy damage," while VisionBit’s cutting-edge vision system tackles the new challenge of "poor recognition and inaccurate grabbing." Together, these innovations have seamlessly transformed flexible manufacturing from a concept into a tangible reality.

Conclusion: Redefining the New Heights of Smart Manufacturing Through Collaborative Innovation. The collaboration between Qianhao Magnetic Electric and VisionBit is not merely a simple combination of technologies—it’s a seamless ecosystem integration of "hardware + software" and "execution + perception." With Qianhao Magnetic Electric’s core expertise in permanent magnet technology and VisionBit’s robust support from AI-powered 3D vision, the jointly developed intelligent material handling and sorting production line is rapidly becoming the cornerstone for heavy industry manufacturers transitioning from "automation" to "intelligence." Looking ahead, both companies will continue to deepen their partnership, pushing technological boundaries even further in extreme environments such as high temperatures and heavy loads—ultimately enabling "Made in China" smart manufacturing solutions to benefit more global manufacturing enterprises.

Does not involve advertising laws, and avoids false or exaggerated promotional claims.

Recommended News

Share