Qianhao Magnetic Electric: From the Capital of Electromagnets to a Pioneer in Permanent Magnet Technology, Forging a New Paradigm for China's Manufacturing

Data Source:

Author:

Publish Time:

2025.08.15

In Yueyang, Hunan—a city hailed as China's "Electromagnetic Capital"—a quiet industrial revolution is reshaping the global landscape of magnetic equipment. Hunan Qianhao Magnetic Electric, a company founded in 2002, has spent the past 23 years making a transformative leap from traditional lifting electromagnets to electro-permanent magnet technology. Not only has it filled the domestic gap in high-end magnetic equipment, but it has also broken through foreign technological barriers through independent innovation, serving as a vivid testament to China's manufacturing industry as it undergoes a dynamic upgrade and transformation.

Breaking the Impasse: From the Pains of Being the "Capital of Electromagnets" to a Breakthrough in Electric Permanent Magnet Technology

In the 1960s, Yueyang laid the industrial foundation for China's magnetic equipment sector, thanks to the rise of the state-owned Lifting Electromagnet Factory. However, during the wave of state-owned enterprise restructuring in the late 1990s, this once-prominent industry briefly hit a low point. The establishment of Qianhao Magnetic Electric coincided precisely with the critical period when global manufacturing was undergoing a transformative shift toward智能化 (intelligent) and green technologies.

"Traditional electromagnets rely on continuous power supply, resulting in high energy consumption and posing a risk of demagnetization. However, electric permanent magnet technology—thanks to its unique feature of 'activating with power and retaining magnetism when power is off'—perfectly addresses this critical pain point," recalled the Technical Director of Qianhao Magnetic Electric Technology. Back in 2002, the company boldly entered the electric permanent magnet field, becoming one of the first domestic enterprises to develop electric permanent magnet lifting devices and suction cups. By adopting a differentiation strategy, Qianhao successfully avoided cutthroat competition with homogeneous products, instead focusing on niche applications such as heavy-duty workpiece handling and precision machining. Over time, the company has steadily built robust technological barriers, now offering a comprehensive product portfolio that includes electric permanent magnet lifting tools, rapid die-changing systems, magnetic templates, and more."

Innovation: China's "China Solution" for Electromagnetic Permanent Magnet Technology Breaks Foreign Monopoly

In Qianhao Magnetic Electric's production workshop, one set of figures stands out: the electro-permanent lifting magnet can handle a single lift of up to 1.2 tons, with a magnetization time of just 0.1 second—and its operational energy consumption is 90% lower than that of conventional electromagnets. Behind these impressive metrics lie Qianhao's profound breakthroughs in magnetic circuit design and materials science.

Case 1: Sany Group's Intelligent Production Line

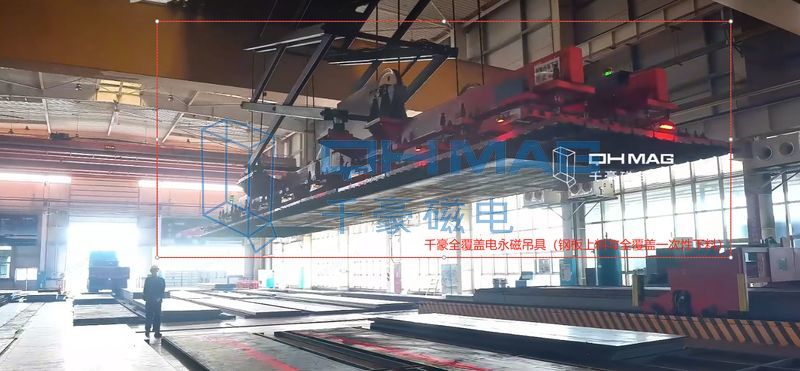

At Sany Heavy Industry's Factory No. 18, the Qianhao Electric Permanent Magnet Lifting Device, combined with Dongpu Crane's Intelligent Gantry System, has created the world's first fully automated intelligent steel plate handling system powered by electric permanent magnets. The lifting device precisely grips steel plates ranging from 4.5 to 20 meters in length, boosting material-handling efficiency by 95% while reducing labor costs by 80%.

Standard: Establishing rules to lead the industry's intelligent upgrade

Qianhao Magnetic Electric's ambitions extend far beyond technological breakthroughs. In 2024, the company participated in drafting the group standard "Intelligent Heavy-Duty Steel Plate Transport Line" (T/CSCMA 0019—2024), integrating electro-permanent lifting magnets as a core component of the intelligent transport system. This standard sets forth critical specifications such as magnetic field distribution and safety protocols, driving the industry’s evolution from "stand-alone automation" toward "system-level intelligence."

“In the past, heavy-load transportation relied on imported equipment, but now our standards have been adopted by several leading enterprises,” said the head of Qianhao’s Standardization Department. Currently, their electric permanent magnet lifting devices have already found applications in fields such as shipbuilding and the automotive industry, enabling flexible “one-suction, one-release” operations—like handling 20-ton steel coils—in various scenarios.

Resonance: The Chinese Manufacturing Spirit Behind the Tiny Magnet

From the decline of Yueyang State-Owned Electromagnet Factory to the rise of Qianhao Magnetic Electric, this trajectory reflects the transformative key to China's manufacturing evolution:

- Independent innovation : Breaking through "bottleneck" technologies, with over 15 electric permanent magnet patents, we have established comprehensive control spanning the entire chain—from materials to systems;

- Standard Leadership : Leveraging group standards as a pivotal point to promote the China Solution as global norms;

- Ecological Co-creation : Forming innovative consortia with companies like VisionBit and Messer, and building an open industrial ecosystem.

As the General Manager of Qianhao Magnetic Electric stated: "Though small in size, electric permanent magnets carry the mission of propelling China's manufacturing industry to leap from 'scale advantage' to 'technological superiority.' In high-end sectors such as new-energy vehicles and aerospace, Qianhao is actively developing next-generation electric permanent magnet products that are both heat-resistant and interference-proof, aiming to achieve an import substitution rate exceeding 90% by 2030."

Conclusion

From workshop-style production along the banks of Yueyang River to becoming a standard fixture in smart factories worldwide, Qianhao Magnetic Electric's 23-year journey epitomizes China's manufacturing story of "breaking barriers—driving innovation—leading the way." As electric permanent-magnet lifting devices gracefully perform on Sany Heavy Industry's production lines, and as Chinese standards begin shaping the global rules for magnetic equipment, we’re witnessing not just the growth of a single enterprise, but also the reconfiguration of a nation’s influence in the era of Industry 4.0. This is precisely the most inspiring resonance of "Made in China."

Does not involve advertising laws, and avoids false or exaggerated promotional claims.

Recommended News

Share