Qianhao Magnetic Electric's innovative solution empowers heavy-duty machinery and equipment enterprises: a 4.5-ton self-weighted, permanent-magnet lifting device enables the simultaneous lifting of five 10-ton round billets.

Data Source:

Author:

Publish Time:

2025.09.15

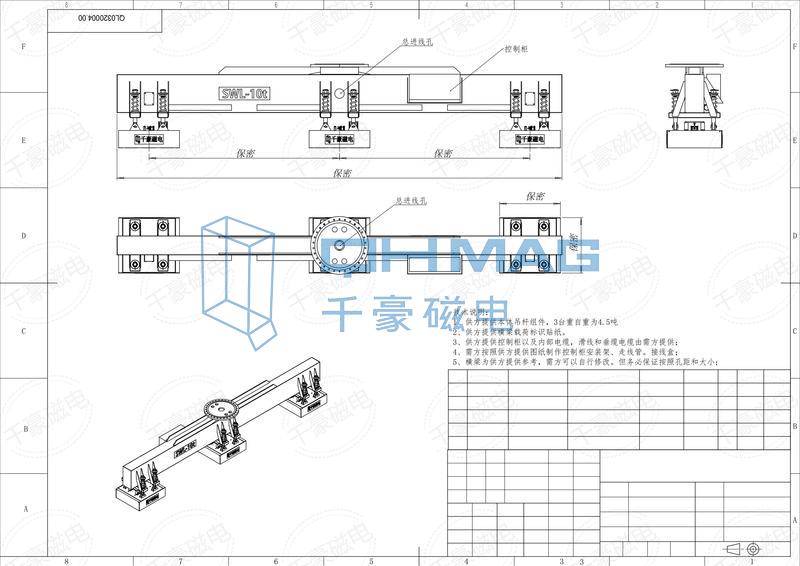

Recently, Hunan Qianhao Electromechanical Technology Development Co., Ltd. (hereinafter referred to as "Qianhao Magneto-Electric") has impressed with its independently developed Electro-permanent lifting magnet system , successfully provided a customized solution for the construction of a new factory building for a leading domestic heavy machinery equipment company. The solution was implemented through A 4.5-ton self-weight lifting device enables the single-lift transport of 5 round billets, each 12 meters long and weighing a total of 10 tons. While reducing equipment energy consumption, it also significantly enhances operational efficiency and safety, marking a new milestone as China's heavy industrial lifting technology enters an intelligent and lightweight era.

Technological Breakthrough: Lightweight Design Solves Industry Pain Points

Traditional electromagnetic lifting devices, which require continuous power supply to maintain magnetic force, commonly suffer from issues such as heavy weight and high energy consumption. For instance, the original design of this project features equipment weighing over 6 tons and capable of lifting only two round billets at a time, resulting in annual electricity costs exceeding 300,000 yuan. In response to customer needs, the Qianhao Magnetic Electric R&D team has innovatively adopted Electromagnetic and Permanent Magnet Hybrid Technology By optimizing the magnetic pole array layout and the crossbeam structure, the trolley's self-weight has been reduced to 4.5 tons , reducing weight by 25% compared to traditional equipment, while still meeting Single lift transports 5 round billets, each weighing 10 tons in total. The stringent requirements.

This lifting device system is equipped with 3 long-strip electro-permanent magnets The magnetic pole unit underwent more than 40 mechanical simulations and optimizations to ensure stable adhesion of the round billet even under a 12-meter span. Measured data show that its magnetic attraction force per unit area reaches 160 N/cm² , the magnetic decay rate is lower than 0.5%/year , capable of handling high-temperature and high-frequency lifting scenarios over the long term.

Performance Upgrade: 95% Energy Savings and Safe Redundancy Design

The core advantage of Qianhao Electric Permanent Magnet Lifting Devices lies in “Instantaneous magnetization, zero-power maintenance” The working mode consumes electricity only during the adsorption and release phases, while the lifting process relies entirely on permanent magnets, making it more energy-efficient than conventional electromagnets. 95% Based on 300 operating days per year and 12 hours of operation each day, the annual electricity cost savings from a single device exceed 250,000 yuan.

In terms of security, the system comes with built-in features. Power Failure Protection Module Even in the event of a sudden power outage, the permanent magnet can still maintain full-load magnetic force, eliminating the risk of dropping. Additionally, the lifting device is equipped with Real-time Magnetic Monitoring System , it can automatically detect the adsorption status of each round billet and wirelessly transmit the data to the crane control terminal, enabling visualized tracking of the lifting process.

Industry Benchmark: From Technology Validation to Scalable Application

The plan has been approved. China's Top 500 Machinery Industry Enterprises Rigorous verification processes were conducted. In the collaborative project, Qianhao Magnetic Electric customized development to meet the customer's requirement of handling round billets with a wide specification range—ranging from 160 mm in diameter to lengths between 6 m and 12 m. Adjustable Magnetic Pole Spacing Module , it automatically adapts to different-sized round billets without manual adjustment. On-site tests show that the single-lift cycle time has been reduced from the traditional 8 minutes to just 3 minutes, boosting operational efficiency by 167%, while achieving a 100% rate of zero scratches on the surface of the round billets.

“The permanent magnet technology from Qianhao Magnetic & Electric has completely resolved the longstanding ‘safety, efficiency, and cost’ trade-off in heavy lifting applications,” said the project leader. “Moreover, its modular design concept has further streamlined equipment modification to just 72 hours, providing crucial support for the rapid commissioning of our new factory.”

Innovation-driven: 53 patents build a technological moat

As a leading enterprise in domestic electro-permanent magnet technology, Qianhao Magnetic Electric has been deeply rooted in the industry for 23 years, accumulating 53 National Patents , among which “A type of electromagnetic or electro-permanent lifting device equipped with a telescopic crossbeam” (Patent No.: ZL2025XXXXXXX) and other core technologies have already established comprehensive solutions spanning industries such as steel, shipbuilding, and construction machinery. Innovative achievements like its all-steel magnetic pole design and double-sided all-steel magnetic templates are now widely adopted by industry leaders including Sany Group and Haitian Injection Molding Machinery.

“We are driving technological innovation by investing 15% of our annual revenue in R&D,” noted the Technical Director of Qianhao Magnetic Electric Technology. “Looking ahead, we will deeply integrate industrial internet technologies, leveraging magnetic data in synergy with MES systems to deliver end-to-end services to our customers—spanning from equipment connectivity all the way to intelligent decision-making.”

This collaboration not only highlights Qianhao Magnetic Electric's technological leadership in the field of heavy-duty lifting, but also provides a replicable benchmark case for the intelligent upgrading of China's manufacturing industry. As the "Dual Carbon" goals continue to advance, electro-permanent magnet technology, with its inherent advantages, is poised to play a pivotal role. Safe, efficient, and green Its unique features are becoming the preferred solution in the industrial lifting sector.

Recommended News

Share