03

2025-07

In the injection molding industry, where small-batch, multi-variety production is becoming increasingly common, traditional mold changing methods are gradually losing their competitiveness due to low efficiency and high costs. The emergence of Qianhao magnetic mold changing system, with its data-verifiable efficiency improvement and accessible technology, is reshaping the industry's production model.

03

2025-07

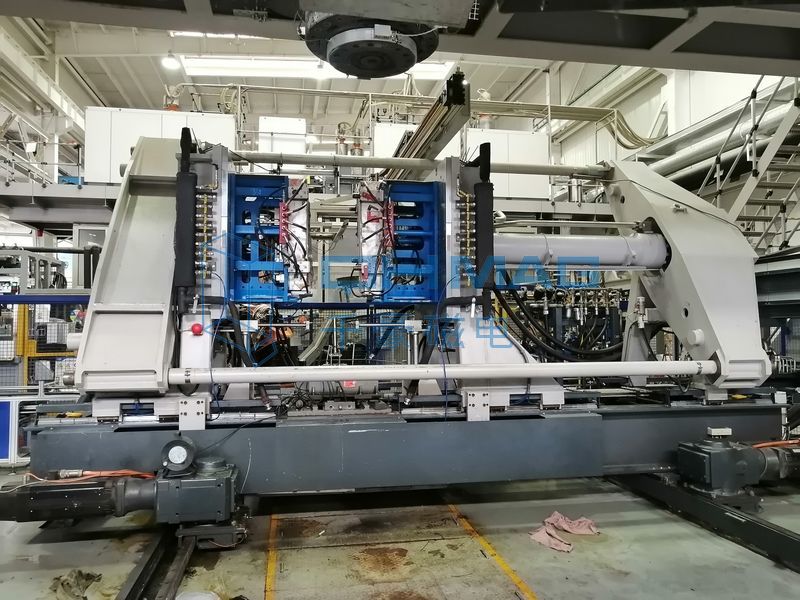

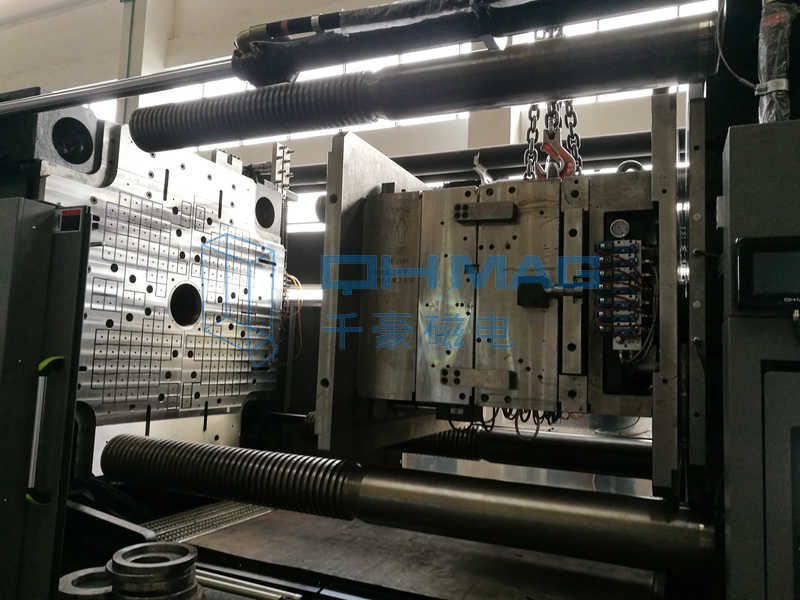

At a plastic factory workshop in Zhejiang, veteran operator Li pressed a control button, and a mold weighing several tons was instantly adsorbed to the injection molding machine template by magnetic force—the whole process took only 3 minutes. A year ago, the same operation required nearly ten workers and two hours to complete.

03

2025-07

Why are magnetic mold changing systems for injection molding machines so popular?

In the injection molding industry, time is money. Every time an injection molding machine stops for mold changes, it means production downtime and increased costs. Therefore, Qianhao's quick mold change system has become a key choice for many companies to improve efficiency. Among various quick mold change technologies, magnetic mold change stands out and is highly regarded.

03

2025-07

In the injection molding industry, mold change efficiency is one of the core indicators for measuring the competitiveness of a production line. The mold change time of several hours with traditional mechanical locking methods has become a bottleneck restricting capacity improvement. The emergence of Qianhao magnetic mold technology is reshaping the industry landscape with its revolutionary efficiency advantages.

03

2025-07

Against the backdrop of rapid development in the new energy vehicle industry, injection molded parts, as core components of vehicle interiors and exteriors, are becoming a new focus of competition among automakers in terms of production efficiency and flexibility. In the face of demands for multi-model parallel development and small-batch customized production from companies such as Xiaomi, Li Auto, and NIO, traditional injection molding machine mold changing methods can no longer meet the requirements of efficient and precise production. The rise of Qianhao magnetic mold technology is providing an innovative solution to this pain point.

03

2025-07

Components and Precautions of a Quick Mold Change System

The Qianhao quick die-change system is a key technology for improving production efficiency and flexibility. Its main components include the following: 1. Magnetic templates: Magnetic templates are divided into moving and stationary mold sides and are the core components of the system. They use permanent magnetic materials to achieve quick positioning and fixing of the molds. 2. Main electrical control cabinet: Responsible for the control and power distribution of the entire die-changing system. 3. Remote controller: Allows operators to remotely operate the die-changing process, improving convenience and safety.