10

2025-11

Qianhao Magnetic Electric's Application Cases and Strength Analysis in Port Terminal Logistics

Qianhao Magnetic Electric's magnetic control system, designed specifically for Liangshan Port, has successfully achieved unmanned stacking of steel coils weighing over 35 tons, setting a new industry record with millimeter-level positioning accuracy. The system leverages electro-permanent magnet technology to precisely grip and release the steel coils, eliminating the risk of coil slippage—commonly caused by human error in traditional lifting equipment—while simultaneously boosting stacking efficiency by 40%. This groundbreaking application underscores Qianhao Magnetic Electric's core technological strengths in handling ultra-heavy materials: high precision, exceptional stability, and full-process automation.

10

2025-11

Recently, Qianhao Magnetic Electric's independently developed next-generation electro-permanent lifting system successfully completed acceptance testing and was officially put into operation at a major domestic port. The system consists of five high-precision electro-permanent magnet units, seamlessly integrated with an intelligent lifting beam via flexible soft connections. It effectively addresses the longstanding challenges of unstable adhesion and cumbersome operations typically encountered with conventional lifting equipment in complex handling scenarios, offering a safe, efficient, and versatile solution for industries such as steel logistics and heavy-load handling.

19

2025-09

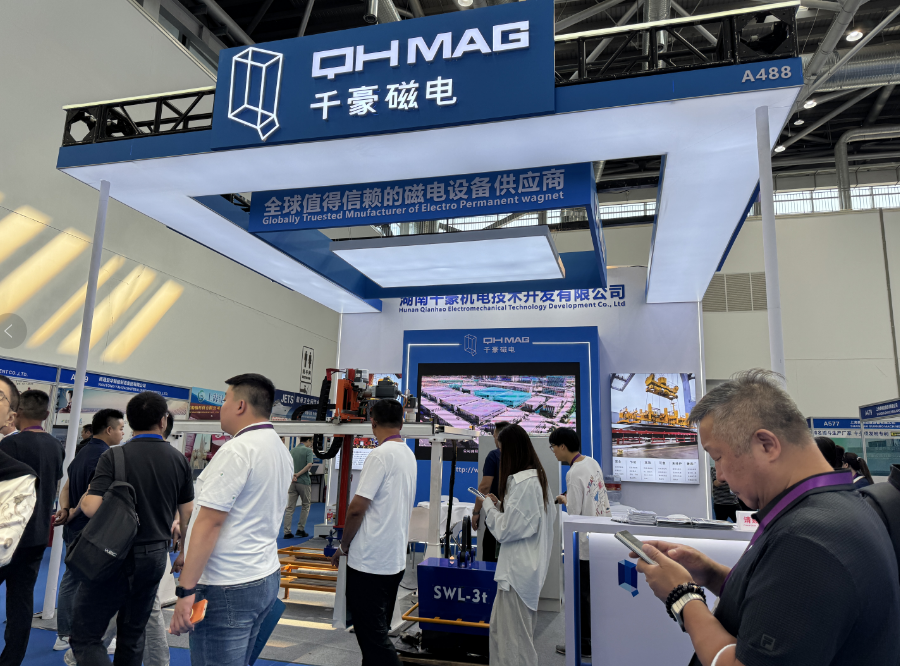

The three-day 2025 Nantong Shipbuilding Industry Expo concluded successfully yesterday (September 18, 2025). As a key event in the shipbuilding industry, this year’s expo brought together numerous domestic and international companies and industry professionals, showcasing cutting-edge technologies and innovative achievements in shipbuilding. Among them, Qianhao Magnetic Electric’s booth at A488 drew continuous attention from exhibitors and shipbuilders thanks to its core technology products and strong expertise, making it one of the highlights of the event.

15

2025-09

Recently, Hunan Qianhao Electromechanical Technology Development Co., Ltd. (hereafter referred to as "Qianhao Magneto-Electric") successfully provided a customized solution for the construction of a new factory building by a leading domestic heavy machinery equipment company, thanks to its independently developed electric permanent-magnet lifting system. This innovative solution utilizes a 4.5-ton self-weight lifting device capable of handling five cylindrical billets at once—each measuring 12 meters in total length and weighing up to 10 tons—thereby reducing equipment energy consumption while significantly enhancing operational efficiency and safety. This breakthrough marks a new milestone for China's heavy industrial lifting technology, propelling it into an era of智能化 (intelligent) and 轻量化 (lightweight) advancements.

15

2025-08

In Yueyang, Hunan—a city hailed as China's "Electromagnetic Capital"—a quiet industrial revolution is reshaping the global landscape of magnetic equipment. Hunan Qianhao Magnetic Electric, a company founded in 2002, has spent the past 23 years making a transformative leap from traditional lifting electromagnets to advanced electro-permanent magnet technology. Not only has it filled the domestic gap in high-end magnetic equipment, but it has also broken through foreign technological barriers through independent innovation, serving as a vivid testament to China's manufacturing industry as it undergoes a dynamic upgrade and transformation.

14

2025-08

At a critical juncture in the intelligent transformation of the heavy industry manufacturing sector, Hunan Qianhao Magnetic Electric Co., Ltd. (hereinafter referred to as "Qianhao Magnetic Electric") has formed a powerful partnership with VisionBit Robotics. By combining Qianhao Magnetic Electric's decades-long expertise in electro-permanent magnet technology with VisionBit's cutting-edge "AI + 3D Vision" capabilities, the two companies are jointly developing a next-generation smart material handling and sorting production line. This innovative line directly addresses key pain points in the heavy industry—such as low sorting efficiency, high labor costs, and challenges in adapting to diverse environments—by leveraging the deep synergy of "electro-permanent magnet adsorption" and "visual navigation." It enables full-process automation, from workpiece identification and gripping after cutting to palletizing, further enhancing the intelligent manufacturing capabilities of leading enterprises like Sany Heavy Industry, Zoomlion, and Taiheavy Group, and equipping them with an even more powerful "smart manufacturing tool."