How to lift steel plates? Have you ever seen this "magnetic suction" 30-ton extra-large steel plate non-destructive lifting tool?

Data Source:

Author:

Publish Time:

2025.07.19

In steel plate hoisting operations, pain points have long plagued related companies. Heavy steel plates are extremely heavy, and traditional hoisting methods are not only time-consuming and laborious but also present numerous safety hazards. Traditional hoisting devices mainly include steel wire rope binding, hook suspension, and clamp clamping. However, steel wire rope binding can easily cause the steel plate to swing and slip, and it can also cause compression and deformation of the steel plate edges; hook suspension has high requirements for the flatness of the steel plate, and uneven steel plates are difficult to hoist stably; clamp clamping is easy to leave clamp marks on the surface of the steel plate, affecting the appearance and quality of the steel plate. At the same time, for ultra-thin or oversized steel plates, traditional hoisting devices are often difficult to adapt to, resulting in low hoisting efficiency.

To solve these hoisting problems, Qianhao Magnetic Electric has launched a series of magnetic suction devices, including permanent magnet cranes and lifting electromagnets, with the electro-permanent magnet being the best among them. The electro-permanent magnet is a perfect combination of the advantages of permanent magnets and electromagnets. It inherits the characteristics of permanent magnets that do not require continuous power supply to maintain magnetism, saving energy and remaining stable adsorption in the event of a sudden power failure to ensure safety; at the same time, it also has the advantage of electromagnets that can control the magnetic switch through current, making operation convenient and flexible. As an upgraded product, the electro-permanent magnet responds quickly and has precise magnetic force adjustment, better meeting the requirements of automation and high efficiency in modern intelligent production, and also meeting the strict standards of safe production, fundamentally changing the predicament of traditional steel plate hoisting.

Qianhao Magnetic Electric has numerous successful cases in the field of heavy steel plate hoisting. In the steel plate logistics park, its electro-permanent magnet hoisting device can hoist 30 1.5mm steel plates at one time (32 in the picture is an over-limit test; the safe usage range is 30 1.5mm steel plates), which can achieve single suction and single release, and can also achieve multiple suction and single release. With precise magnetic force adjustment, it meets the needs of efficient sorting and transportation in the logistics park. In the Hengli Shipyard, for the hoisting of 30-ton steel plates, the electro-permanent magnet hoisting device provided by Qianhao demonstrates excellent safety. Based on the design of beam gravity, combined with the powerful pull-off force data of the electro-permanent magnet, it ensures the stability and reliability of the heavy steel plate hoisting process.

In the steel plate blanking industry, Qianhao's nationwide full-coverage electro-permanent magnet hoisting device is used in Sany Heavy Industry Ningxiang Lighthouse Factory. This hoisting device can transport more than 300 types of parts after cutting, together with scraps, at one time, achieving no leakage suction and no vertical suction, greatly improving the operation efficiency of the blanking process.

Whether you are in automobile manufacturing, shipbuilding, railway groups, or other companies involved in steel plate handling, clamping, and adsorption, Qianhao Magnetic Electric's magnetic suction method electro-permanent magnet is the ideal choice. Qianhao's four major products—electro-permanent magnet hoisting devices, electro-permanent magnet chucks, electro-permanent magnet clamps, and quick mold change systems—can comprehensively solve the problems encountered in steel plate processing in various industries, providing efficient, safe, and convenient solutions for your production operations.

Qianhao electro-permanent magnet: An ant's body carries the strength of an elephant, reshaping the new paradigm of automated tooling fixtures.

Main Text:

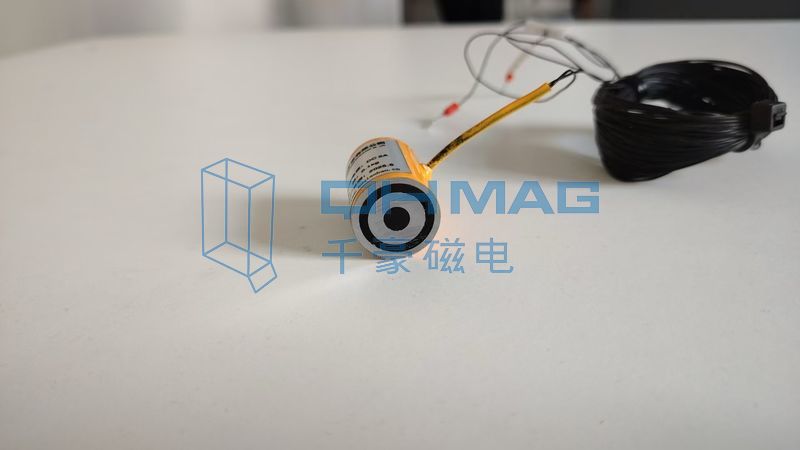

In the "slimming revolution" of automated industry, a miniature electro-permanent magnet with a diameter of only 20mm and a self-weight of 0.1kg is subverting the traditional understanding of tooling fixtures with the posture of "an ant moving an elephant." Launched by Hunan Qianhao Magnetic Electric, the QEPMZ-C20 series electro-permanent magnet, with its amazing 6kg suction force and DC170V low-voltage design, has set off a technological revolution in the fields of automobile sheet metal handling and precision machinery processing, becoming a phenomenal product in the 2025 automated equipment market.

Technological Breakthrough: Great Energy in a Small Size

The core advantage of QEPMZ-C20 lies in its Electro-permanent dual magnetic source technology :

- Extremely small size, ultimate performance : With a compact structure of 20mm in diameter, it achieves a suction force of 6kg, with a suction force density more than 3 times that of traditional electromagnets, and can easily adsorb automobile sheet metal parts as thin as 0.8mm.

- Zero energy consumption to maintain magnetic force : It only consumes electrical energy during magnetization/demagnetization (0.1 seconds, DC2A), and does not require continuous power supply during operation, with an energy saving rate exceeding 95%, completely solving the safety hazard of electromagnets losing magnetism due to power failure.

- Excellent environmental adaptability : High temperature resistant, shock resistant, surface residual magnetism is close to zero, avoiding magnetic chips from adhering to and scratching workpieces, suitable for precision manufacturing scenarios.

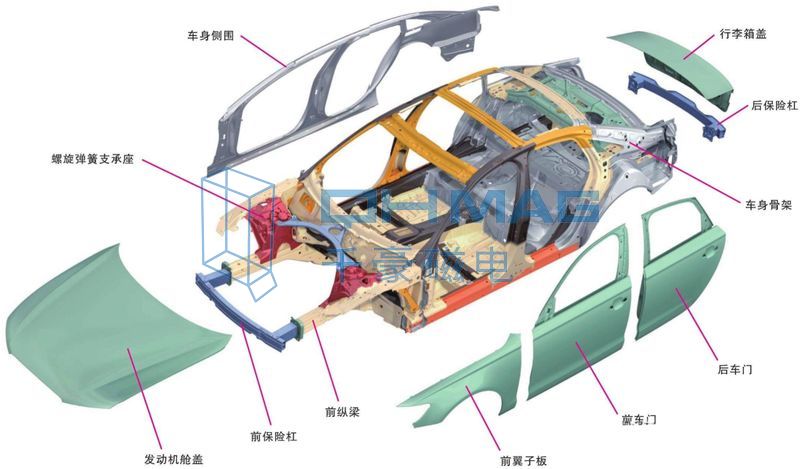

Application Scenarios: Revolutionizing Automated Handling in the Automotive Industry

In the automobile body-in-white welding line, Qianhao electro-permanent magnets have become Flexible production Key components:

-

Efficient grasping of thin sheet metal : Multiple QEPMZ-C20s are integrated at the end of the robotic arm, and through distributed magnetic force control, curved and irregularly shaped sheet metal parts can be stably adsorbed, solving the problems of traditional vacuum suction cups easily leaking air and mechanical clamps deforming workpieces.

-

Quick mold change system : Matched with magnetic force templates, it enables quick replacement of injection molding machine molds within 3 minutes, increasing production capacity by 40%, and has been applied to the supply chain systems of leading automakers such as BYD and Tesla.

-

Data Confirms Value : Tests by a leading automaker show that after using Qianhao electro-permanent magnet clamps, production line downtime is reduced by 60%, and single-shift handling efficiency is increased by 25%.

Industry Trend: Electro-permanent Magnet Technology Drives Green Manufacturing

According to the "2025 Tooling Fixture Industry Prospect Analysis," the global tooling fixture market size will exceed US$80 billion, of which Intelligent and energy-saving have become core needs. Qianhao Magnetic Electric's electro-permanent magnet technology is in line with this trend:

-

Compared with traditional electromagnets : Eliminates the need for continuous power supply battery packs, reducing equipment weight by 30% and carbon emissions by 90%.

-

Modular design : Supports building-block combinations, adapting to different workpiece specifications, and solving the pain points of "multi-variety, small-batch" production in the automotive industry.

-

Policy benefits : Selected into the Ministry of Industry and Information Technology's "Intelligent Manufacturing Special Project Guide," awarded as a Hunan Province "Specialized, Refined, Special, and New" enterprise, and technical standards included in the "National Standard for Electro-permanent Magnet Chucks".

Qianhao Magnetic Electric: A "Hidden Champion" in the Electro-Permanent Magnet Field

As a technology inheritor of Yueyang's "Electromagnetic Capital," Qianhao Magnetic Electric has been deeply engaged in the electro-permanent magnet field for 23 years, holding 18 core patents. Its products cover four series: lifting devices, suction cups, clamps, and magnetic templates. Electro-permanent magnet rapid mold change system It has occupied 65% of the domestic high-end injection molding machine market, with customers including leading enterprises such as CRRC and Sany Heavy Industry.

Future Outlook

With the surge in demand for lightweight new energy vehicles, Qianhao Magnetic Electric is developing High-temperature electro-permanent magnets (operating temperature up to 150℃) and Wireless controlled magnetic units The goal is to achieve an electro-permanent magnet technology penetration rate of over 50% in the automotive manufacturing field by 2028. This "ant-sized" tooling fixture is injecting "small but beautiful" strong magnetic power into China's intelligent manufacturing with disruptive innovation.

Data Source Qianhao Magnetic Electric Laboratory, "2025 China Permanent Magnet Motor Market Report," China Association of Automobile Manufacturers, Report.cn.

Recommended News

Share