Ant Power' Leverages Automotive Manufacturing: Qianhaodian Permanent Magnets Reshape the Automation Production Line Fixture Pattern

Data Source:

Author:

Publish Time:

2025.07.21

In the wave of automotive manufacturing automation, the performance of tooling directly determines the flexibility and efficiency of the production line. With its technological breakthrough of "small size, large suction force," Qianhao Dian's electropermanent magnets have become a key enabler for automated automotive production lines, particularly demonstrating irreplaceable advantages in precision processes such as sheet metal handling.

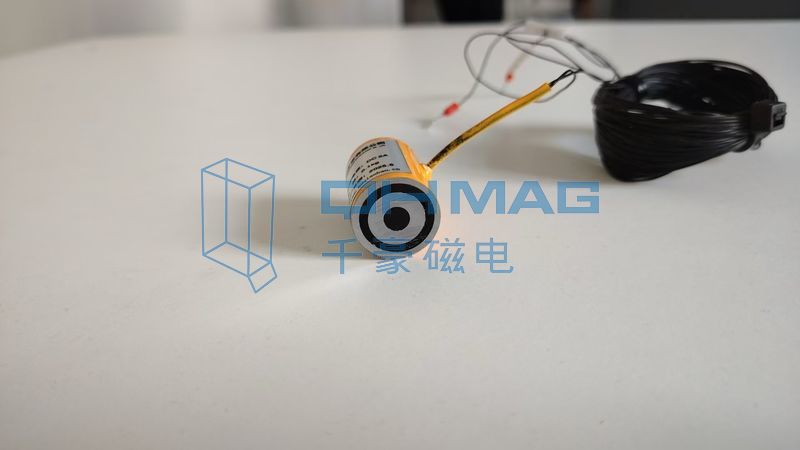

The QEPMZ - C20 model in the Qianhao Dian electropermanent magnet family is a miniature power marvel: with a diameter of only 20mm and a weight of 0.1kg, its "small size" can generate a powerful suction force of 6kg. Its power parameters achieve a rarely seen power density ratio of 60:1 in the industry. This model uses a 170V DC power supply, with a stable operating current of 2A, achieving energy optimization while ensuring high efficiency. This "ant moving an elephant" performance stems from its unique magnetic circuit design—through the synergy of rare-earth materials and an electromagnetic control system, the magnetic field intensity is precisely focused on the adsorption surface, maximizing the utilization of magnetic field energy within a minimal volume.

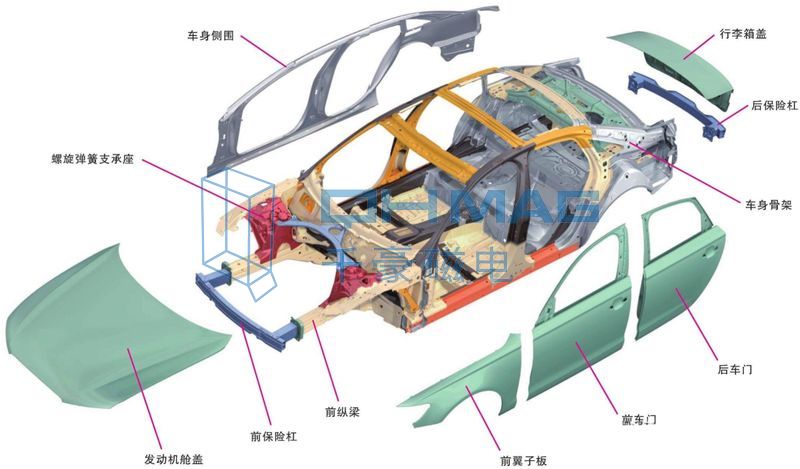

In the automotive body-in-white manufacturing process, this characteristic demonstrates revolutionary value. Automotive sheet metal parts generally have thin thicknesses (0.8 - 2mm), complex curves, and stress deformation issues. Traditional mechanical fixtures can easily cause damage to workpieces or unstable clamping. Qianhao Dian electropermanent magnets, through modular deployment solutions, integrate multiple sets of miniature electropermanent magnetic units at the end of the robotic arm, using a distributed magnetic field to cover the surface of irregular workpieces. Its non-contact adsorption characteristics can avoid mechanical stress, and combined with an intelligent magnetic control system, it achieves millisecond-level magnetization and demagnetization response. The sheet metal handling efficiency of a single robotic arm workstation is increased by 40%, and the defect rate is reduced to below 0.03‰.

Practical data from a leading automaker shows that after adopting the Qianhao Dian electropermanent magnet tooling system, the changeover time of its side-outer panel automated production line was reduced from 30 minutes with traditional fixtures to 1 minute, and the overall equipment effectiveness (OEE) increased by 22%. This flexible advantage allows it to quickly adapt to the switching of sheet metal parts for different models, perfectly matching the current automotive industry's trend of multi-variety and small-batch production.

Qianhao Dian electropermanent magnets' technological breakthroughs are not only reflected in physical performance but also restructure the design logic of automated production lines. Its non-contact wear and oil-free pollution characteristics significantly reduce equipment maintenance costs; while the power-off non-demagnetization safety design provides double protection for production line safety redundancy. As automotive manufacturing upgrades towards lightweight and intelligent features, Qianhao Dian electropermanent magnets are evolving from auxiliary tooling to core power units for automated production lines, driving automotive intelligent manufacturing towards higher precision and greater flexibility.

Recommended News

Share