Qianjia Electric's permanent magnet revolutionizes automotive manufacturing automation (Qianhao Express News)

Data Source:

Author:

Publish Time:

2025.07.22

A magnet unit with a diameter of 20 millimeters and weighing only 100 grams can firmly hold a 6-kilogram car body panel, performing high-precision "air ballet" at the end of a robotic arm.

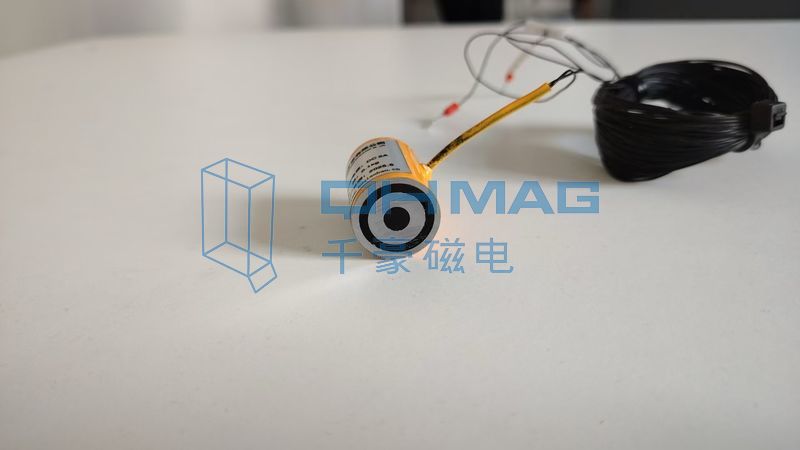

In the laboratory of Hunan Qianhao Electromechanical, engineers placed a 0.8-millimeter-thick car door panel on the test bench. With the command issued, a group of electro-permanent magnets, only the size of coins, were instantly activated. The thin steel plate was steadily adsorbed and lifted. Even with manual shaking, it remained motionless. Even more surprising, when the engineer suddenly cut off the power, the sheet metal remained firmly attached to the magnetic suction unit—this is Qianhao's latest generation QEPMZ-C20 electro-permanent magnet demonstrating its "power remains after power off" core technology.

" 6kg suction force, 0.1kg self-weight power density makes the miniature electro-permanent magnet a key driver of flexible manufacturing in automated automotive production lines. Qianhao's R&D director introduced at the technical launch. 。”千豪研发总监在技术发布会上这样介绍。

01 Disruptive Magnetic Technology

In the automotive manufacturing field, the handling of car body panels has always presented unique challenges: The sheet metal is less than 6 millimeters thick, and the surface is uneven. Traditional vacuum suction cups require a perfect seal, while mechanical clamps can easily cause deformation.

Qianhao Electromechanical's QEPMZ-C20 electro-permanent magnet unit , with a diameter of only 20mm and a self-weight of 0.1kg, provides up to 6kg of vertical suction force . This miniature magnetic control unit, with a working voltage of DC170V and a current of 2A, is redefining the tooling design logic of automated automotive production lines.

Its core technology lies in the unique dual-mode magnetic circuit system —after activating the neodymium iron boron permanent magnet with a pulsed current , the magnetic field can be self-sustaining; a reverse current pulse achieves instantaneous demagnetization6. This operating mode solves the pain point of continuous energy consumption of electromagnets and overcomes the defect that traditional permanent magnets cannot be quickly demagnetized.

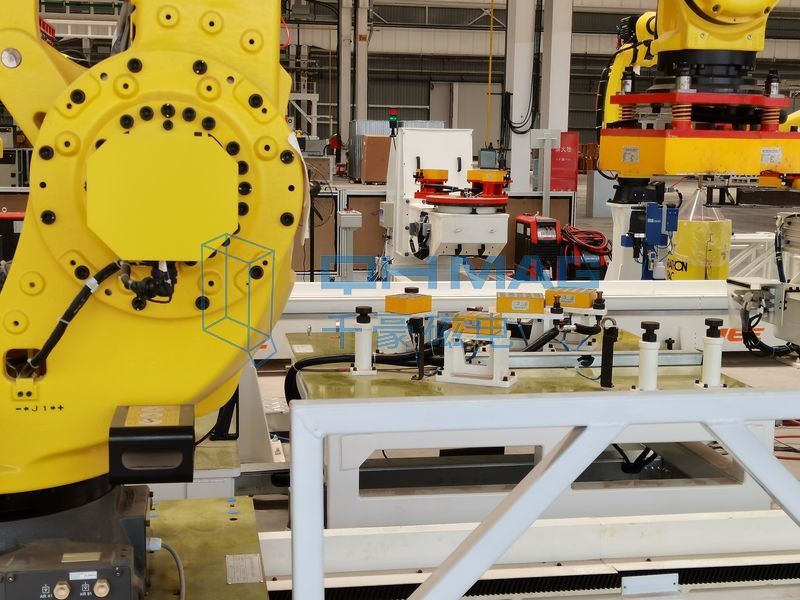

"Imagine that hundreds of such magnetic control units can be densely arranged on the tooling plate at the end of the robotic arm, like Lego blocks ." Qianhao's chief engineer explained, "Each unit is independently controllable and can adapt to sheet metal parts of various curved shapes, which is a flexibility that rigid fixtures cannot achieve."

02 Transformative Applications in Automotive Production Lines

In the stamping workshop of a modern automobile factory, the QEPMZ-C20 array is demonstrating revolutionary value. When the end of the robotic arm is equipped with an adsorption matrix composed of dozens of C20 units, the system can achieve:

Intelligent surface fitting : Through zonal magnetic control technology, the tooling automatically adjusts the magnetic force distribution, closely fitting the complex curved surfaces of parts such as engine hoods and doors, eliminating the risk of falling off caused by air leakage in traditional vacuum suction cups.

Multi-pose processing : In the welding workshop, the chassis is firmly fixed by magnetic tooling, and the robotic welding arm can perform 360° all-angle welding. Magnetic adsorption makes the workpiece evenly distributed , avoiding local deformation and ensuring welding accuracy.

Millisecond-level response : The charging and discharging process is controlled to be completed within 0.1 seconds , more than 5 times faster than pneumatic fixtures. When the production line switches models, the magnetic tooling does not require mechanical adjustment; the magnetic pole combination can be adapted to new workpieces by switching programs.

A bending intelligent workstation at a branch of Sany Heavy Industry verified the potential of this technology: A robot arm with 5 Qianhao miniature electro-permanent magnets installed achieved free flipping and precise bending of workpieces. The workshop manager feedback: " Previously, various fixtures were tried, but none could complete such complex multi-angle operations ”。

03 Breakthrough Advantages in Engineering Design

For automotive production line planners, Qianhao miniature electro-permanent magnets bring three major technological benefits:

Spatial revolution : Traditional pneumatic fixtures require complex piping systems, while C20 units are powered by a unified cable. The ultra-thin design with a thickness of only 20mm allows the tooling to reach narrow spaces inaccessible to traditional fixtures.

Energy consumption disruption : Only consumes power during charging and discharging (approximately 0.1 seconds), zero energy consumption during adsorption. Compared to electromagnet systems that continuously consume power, energy costs are reduced by more than 90% 。

Safety redundancy : Using permanent magnet retention principle , even in the event of a sudden power failure, the adsorbed workpiece will not fall. The independent working mode of each unit ensures that the entire system can still operate safely even if a single module fails.

In the actual application of a new energy vehicle factory in Changzhou, the door panel welding line using Qianhao electro-permanent magnet tooling reduced product switching time from 47 minutes to 3 minutes , and the product defect rate decreased by 32%.

04 Tooling Design for the Future

As the automotive manufacturing industry shifts towards a multi-variety, small-batch production model, flexible tooling has become a core pain point in the intelligent upgrading of production lines. Qianhao Electromechanical is promoting the research and development of a third-generation intelligent magnetic control system, which features:

Self-sensing magnetic force adjustment : Real-time monitoring of the adsorption state through pressure sensors, automatically compensating for magnetic force loss caused by uneven workpiece surfaces.

Internet of Things integration : Each magnetic control unit is implanted with a communication chip, and the tooling system can be directly connected to the MES system to realize automatic switching of magnetic force parameters according to the product model.

Composite adsorption scheme : For non-magnetic materials such as aluminum car bodies, magnetic-vacuum hybrid tooling is developed to expand the application boundaries.

" We are transforming from a hardware supplier to a flexible production line design partner ," revealed the person in charge of Qianhao Electromechanical's automotive business unit at the latest technology salon, "Next year, a reconfigurable magnetic suction tooling platform will be launched, and auto factories can adjust the workstation scale like building blocks according to production fluctuations."

Ideal Technical log records of the automobile stamping workshop recorded this change: The engine hood production line, which used to take 20 minutes to switch, is now completed within 90 seconds. Engineers freely arranged 56 QEPMZ-C20 units on the magnetic suction tooling, like arranging chips on a circuit board.

This intelligent matrix composed of miniature magnetic force units can firmly grasp the variably curved automotive body parts, and can release the workpiece within 0.1 seconds, allowing the robotic arm to achieve human-like flexibility. 6。

In the era of Industry 4.0 automotive manufacturing, the key to success is no longer the number of robotic arms, but the intelligence level of each end effector. When millimeter-level magnetic control units dance on the production line, the boundaries of flexible manufacturing are redefined once again.

Recommended News

Share